Product Information

We can create a material formulation

to meet the specific requests of any customer.

You can count on us for prototyping needs as well.

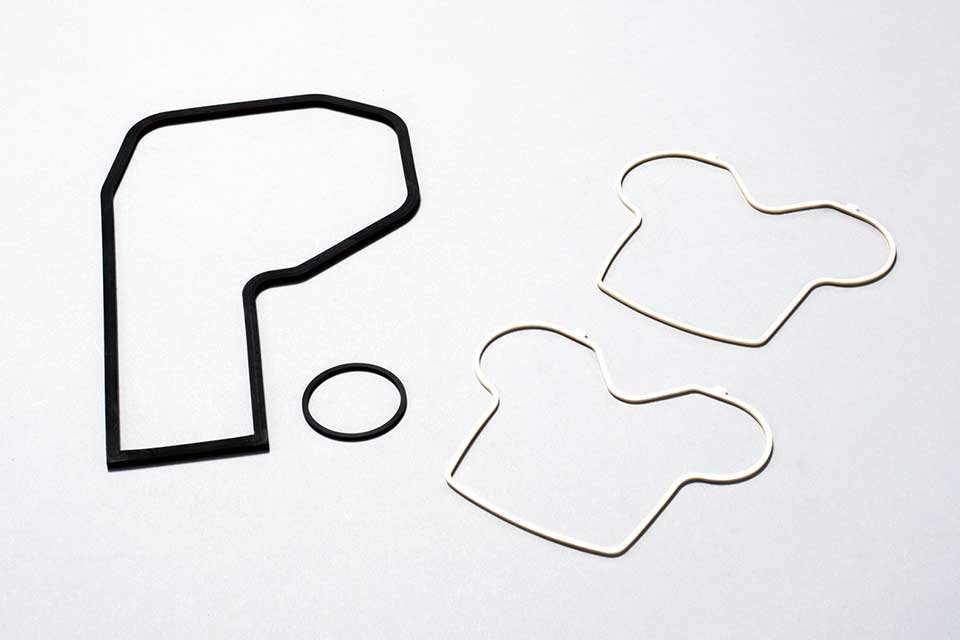

We will create a variety of rubber products based on customer requests.

We also have abundant experience creating complex-shaped products using 3-dimensional metal molds.

Rubber Sponge Products

Rubber Products

Manufacturing Workflow

-

1 Inquiry

From an inquiry or consultation, we conduct interviews related to customer needs.

-

2 Meeting

The production supervisor determines the appropriate manufacturing method through detailed meetings with the customer.

-

3 Material Selection

We select a composite rubber material with the properties the customer is looking for.

-

4 Prototyping

After casting is completed at the Tomisato Factory, we manufacture a prototype product.

-

5 Adjustments

We examine the sample product using a variety of different testing equipment to judge the material.

-

6 Mass Production

If the order is for a new product, mass production starts after repeated prototyping over a period of 1 - 2 years.

-

7 Testing

-

8 Quality Testing

Following the ISO9001 management system model, we conduct quality inspection for each lot.

-

9 Delivery

Our thorough management ensures delivery is completed by the date you request.